- Home

- Industries

- Dairy and Cheese

Process Automation Solutions to Keep Your Operations Running Smoothly

Working as a trusted partner to leading U.S. dairy and cheese producers for more than 29 years, Cybertrol Engineering is a system integrator with extensive experience in sanitary process control and meeting Pasteurized Milk Ordinance (PMO) requirements for the dairy and cheese industry.

Plantwide Automation & Information Solutions for the Dairy and Cheese Industry

From the tanker delivery of milk through final cheese packaging and inventory management, Cybertrol delivers end-to-end integration solutions to optimize production. With best practices learned from hundreds of successfully completed projects throughout the industry, we understand the processes, the regulations, and the operational challenges.

PMO-Compliant Process Control Experts

We have a team of cheese and dairy experts, who understand the industry's unique process requirements. Our engineers have created PMO-compliant process control solutions to ensure raw milk is processed efficiently and with the highest quality standards, while gathering the correct data to create the reports that are required. Cybertrol can effectively control production processes from intake bay management, standardization and pasteurization to recipe management for cheesemaking and dairy mixtures, to flexible and efficient sanitary CIP (Clean-in-Place) processes, ensuring the final product is in-spec and USDA compliant.

- Milk Intake/Storage

- Milk Standardization

- Pasteurization (HTST)

- Homogenization

- Separation

- Filtration

- MES Implementation

- Performance Metrics/OEE

- Batch/Recipe Management

- Vat Automation

- Drying/Evaporation

- Materials Track and Trace

Customer Testimonial

Batch Control Solutions for Cheese & Dairy Manufacturing

Cybertrol Engineering specializes in batch control solutions tailored to the unique challenges of cheese and dairy production. Our expertise in ISA-88 batch control ensures efficient recipe execution, scheduling, and system validation while maintaining compliance with FDA 21 CFR Part 11.

Our solutions integrate seamlessly with MES and ERP systems, providing:

- PLC-based and Server-based batching systems for precise control

- Recipe management with version control

- Batch history logging and reporting

- Real-time inventory accuracy through ERP integration

- Production scheduling and materials traceability

- Utilities optimization for improved efficiency

Our batch control solutions provide a scalable, compliant, and data-driven approach to batch processing, ensuring consistent, high-quality production.

BatchWorks by Cybertrol: Enhanced Batch Control and Flexibility

Cybertrol Engineering’s BatchWorks is a web-based MES software, well-suited for the cheese and dairy industry, providing seamless integration between your production floor and ERP system. By accurately tracking material consumption and production data in real time, BatchWorks enhances visibility into production costs, inventory levels, batch cycle times, and product quality—key factors in ensuring efficient and compliant dairy processing.

Built on the ISA-88 batch control standard, BatchWorks supports phase-based recipe management tailored to the complexities of cheese and dairy production. Supervisors and operators can easily create, copy, and modify recipes, automate batch execution, and make manual adjustments as needed to optimize production efficiency and maintain consistent product quality.

Batch Process Extensibility

BatchWorks MES Software

Electronic Records and Signatures

Cybertrol's extensive experience in the dairy and cheese industry has given us a comprehensive understanding of the electronic record requirements for the FDA and USDA. We specify data acquisition server systems, thoroughly validate systems in-house with test procedures, have written corporate standards to help companies comply with 21 CFR Part 11, and more.

PalletWorks Helps a Large Cheese Manufacturer Solve End-of-Line Errors

PalletWorks, a fully-integrated tracking and labeling software solution from Cybertrol, helped a large cheese manufacturer solve costly end-of-line errors occurring during the transfer of data from the plant floor to the ERP system. The PalletWorks web portal empowers factory floor associates to see the data and correct labeling mistakes before they are transferred to the ERP system, often avoiding loss of product and unplanned downtime. PalletWorks is a unique and creative integrated solution, a bridge between the ERP and PLC on the plant floor.

Case Studies: Dairy and Cheese Industry

Read our cheese powder facility case study

A cheese powder facility was suffering from poor performance being tied to obsolete recipe execution systems and dated PLC/HMI technology.

Read our blue cheese facility case study

A specialty blue cheese producer was building a new facility and needed an advanced solution for automation and information systems.

Cybertrol Engineering is a recognized leader in Batch Control and Recipe Management System Integration.

Batch Control Solutions

Manufacturing Intelligence (MI) Solutions

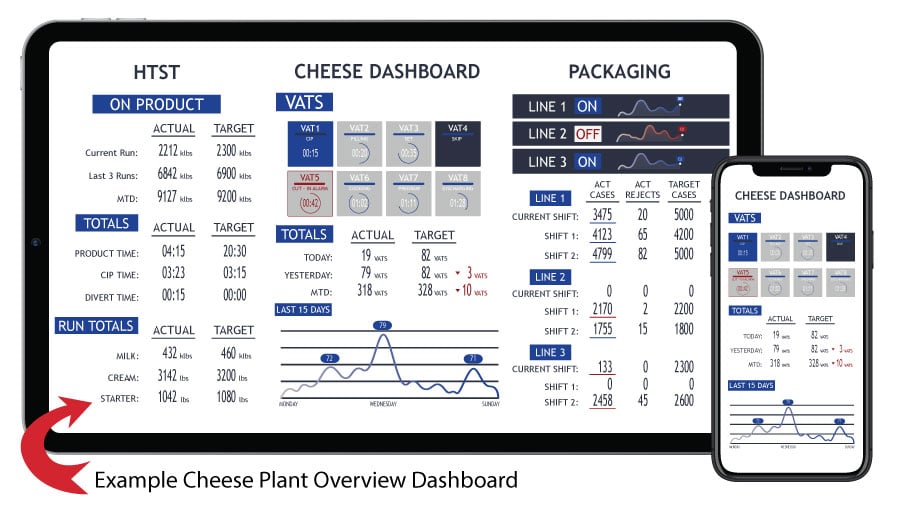

Cybertrol's Manufacturing Intelligence group includes software engineers that provide visibility into the control system through data visibility via reports, dashboards, web pages, or other methods. Our engineers can also provide the ability to connect into ERP systems for advanced integration into the business system when recipe and formulation connections to the plant floor are required. Having a Manufacturing Execution System (MES) that can tie into the control system to track and report on production uptime, Overall Equipment Effectiveness (OEE), quality, or other production related data can be extremely valuable to an operation.

- Report design, definition, build, and deployment using various platforms

- Customer interfacing for data requirements

- ERP integration services when required

- Custom middleware applications when required

- Data collection into time series or event-based databases

Industrial IT/OT Services

Cybertrol's Industrial IT/OT department provides design and implementation of servers and network infrastructure. The OT (Operation Technology) network is the backbone of the entire system and has a large impact on the success of a factory's operation. We have engineers that are certified in Cisco, Microsoft, VMware, Panduit, and many other Industrial IT disciplines.

- Network and server system design and build

- Network physical infrastructure standards

- Server and switch specification and configuration

- Network assessment and mapping

- Onsite network component implementation and configuration

Featured Industry Associations

Featured Case Study

A leading dairy cooperative aimed to establish a state-of-the-art greenfield cheese manufacturing facility. Recognizing the importance of advanced control and monitoring systems, the client sought to integrate a Rockwell Automation PlantPAx 5.0 distributed control system (DCS) with their building automation system (BAS) so they could monitor and manage operations as one unified plant. To achieve this goal, Cybertrol, a trusted automation solutions provider, was chosen to lead the project.

Contact us today to streamline your operations and ensure PMO compliant production.

Contact Us