- Home

- Services / Solutions

- Batch Control & Recipe Management

Flexible Systems to Streamline Batching Processes & Reduce Variability

Cybertrol leverages extensive experience in delivering advanced batch control solutions for complex processes. Our engineers specialize in ISA-88 standards, integrating batch control with MES/ERP systems to enhance production scheduling, recipe management, and lot tracking. With a focus on compliance, we ensure solutions meet FDA 21 CFR Part 11 regulations for electronic records and signatures, providing both flexibility and precision in every project.

Cybertrol Engineering is a recognized leader in Batch Control and Recipe Management System Integration

Cybertrol's experience is the result of numerous, successful batch control system projects for a variety of challenging batch applications. Our engineers are experts at ISA-88 standards for batch control and modeling the enterprise for optimal batch processing. We define batch control and recipe execution solutions for manufacturing operations by analyzing the physical system and the procedural requirements. Cybertrol Engineering will help you understand how batch control systems can facilitate scheduling production, recipe editing, formulations, system validation, lot tracking, flexible requirements, and more.

Our batch control system designs take into consideration FDA 21 CFR Part 11 (Code of Federal Regulations for electronic records and electronic signatures). From system functional requirements specifications to software module construction, Cybertrol’s designs comply with the International Society of Automation standards including ISA-88 and ISA-95 for batch control system design and integration with MES/ERP systems.

- PLC and server-based batching solutions

- Recipe management, storage, and version control

- Batch history logging and recording

- Flexibility to add functionality

- ERP integration for inventory accuracy

- Production scheduling

- Full data collection and reporting

- Materials traceability

- Utilities optimization

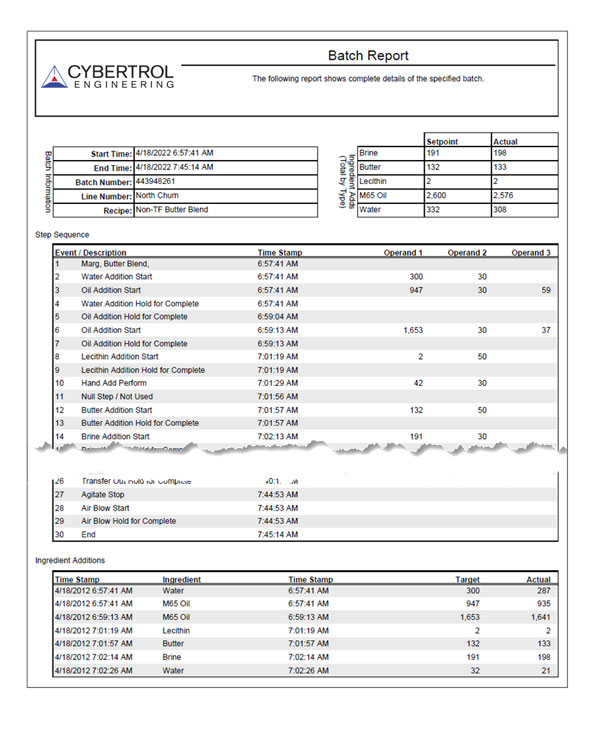

Batch Reports

Detailed Batch Report: This report will show batch start and end times, batch ID, recipe used, and setpoint versus actual for ingredient additions, as well as any other alarms or events that occur during the batch operation.

Completed Batches by Date Report: This report shows all batches that were completed between two user-specified dates. Each batch is shown as a link that navigates to the summary batch report for the selected batch.

Summary Batch Report: The summary batch report can be run for any production batch and shows recipe, run time, and both individual and aggregate (total) ingredient usage by material type.

Golden Batch: Golden batch reports allow for the definition of what an ideal batch should “look like”, then allows for future executions to be compared via the standard using an overlaid trend. A batch is defined as anything with a defined “beginning and end” and could be a batch of product, a CIP wash, or a 24-hour trend of water consumption or effluent discharge.

BatchWorks by Cybertrol Engineering – Batching System Extensibility

Cybertrol Engineering’s BatchWorks is a web-based, MES software that seamlessly transacts material consumption and production information with your ERP system, enabling real-time visibility to production cost, inventory availability, batch cycle time, and batch quality.

The BatchWorks programming strategy utilizes the ISA88 batch control standard for design with phase-based recipes to support the operations of the batch process. Supervisors/operators can create, copy, and modify recipes, run and phase automatic recipe execution, and manually adjust operations.

Enhance Your Batch Process

BatchWorks MES Software

Cybertrol's FactoryTalk Batch Experience

As a Rockwell Automation PartnerNetwork Gold System Integrator, Cybertrol is fully competent with FactoryTalk Batch, a Rockwell Automation software that allows end users to apply one control and information system across their entire process to improve capacity and product quality, save energy and raw materials, and reduce process variations and human intervention.

Using ISA88-based functionality, recipes and processes can be developed independently of process equipment. Users can easily change recipe parameters, add new batches, or define which equipment your batches use; without requiring engineering or automation system changes or revalidation.

With FactoryTalk Batch, end users can:

- Create and manage recipes and execute them automatically

- Reduce hours that are needed for validating and commissioning

- Configure physical and procedural models

- Collect electronic batch data to generate detailed reports for compliance or process improvement

- Simulate the entire batch process

Cybertrol has developed tools to leverage the power of FactoryTalk Batch software along with additional innovations to allow for corporate recipes from the ERP to be pushed into the system, with detailed reporting solutions as a result.

Case Studies: Batch Control Success Stories

Cybertrol designed a flexible batching solution for an ice cream plant to handle dynamic equipment arbitration across 100+ source tanks.

Cybertrol helped a major cheese powder manufacturing facility upgrade to a S88 batching solution, eliminating outdated proprietary software.

Contact Cybertrol Engineering to optimize your batch control and recipe management systems.

Contact Us